12:54 PM

|

| Blade tests |

If we look up to the wind turbine costs. It can be clearly seen that the blades have a huge importance for a wind turbine. Blades are used for capturing energy from the wind. Longer blades mean higher captured power. But when the blade length is increased, beside higher power, higher loads will also occur. After certain wind speed blades won't be able to withstand with higher loads and they will be broken which is not desirable situation. That's why the blade length is optimized.

|

| Blade bending test |

When the rotor is rotating, the blades have a certain rotational speed which is calculated before construction. After certain rotational speed, the turbine must be shut down to prevent collapsing. If not, the blades will turn faster and faster in high wind conditions. And due to high force at the tip of blade, it will tend to bend to the tower. As a result it will hit to tower.

|

| Blade bending test |

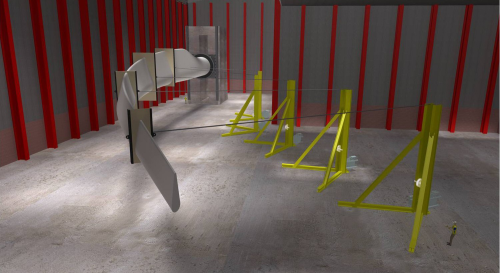

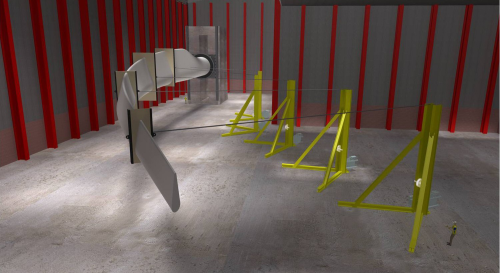

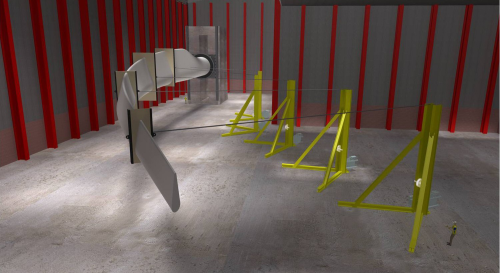

Bending property of the blade is so important and blade frequencies must be also calculated to prevent a resonance effect before construction. Due to all this stuff, some type of tests are made by blade manufacturers. Because they want to be pretty sure that their blades can withstand with all conditions in an efficient way. That's why as a first step, they are investigating the loads and they are making some experiments with blades which are showed in previous pictures.

|

| Blade bending |

As it seen in the previous photo, the tips of the blades bend to the tower due to wind. As in development stage, during investigating the loads, tip to tower distance in all extreme conditions must also be considered as it defined in guidelines.

0 Comments :

Post a Comment